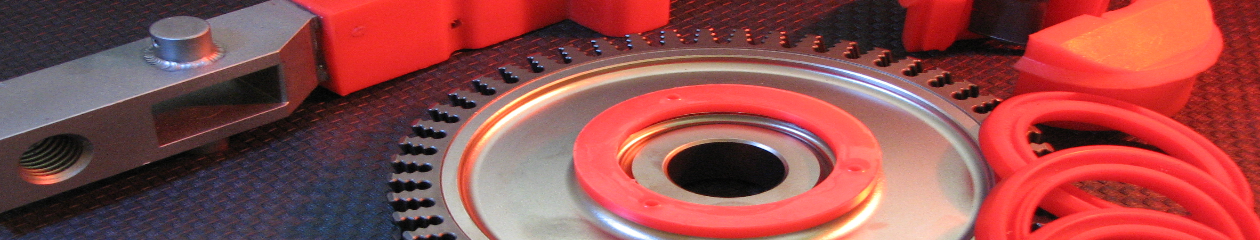

Our damage and abrasion resistant mouldings are a simple but cost effective solution which will protect sensitive areas of components through the various stages of processing, lifting, moving, storage and despatch.

Developed to protect components during our own processing we have now extended this service and produce mouldings directly for our customers.

Using our knowledge and experience, we are able to assess component requirements to produce mouldings to meet customers’ specific needs and reduce unnecessary costs resulting from damage, delays and rework.

All our mouldings are rigorously tested to ensure a high quality of wear resistance enabling them to be recycled many times through the handling stages, and presenting a cost effective solution to damage prevention.

© 2025 Curtiss-Wright Corporation | User agreement | Privacy Policy | Cookies | Sitemap